For many industrial facilities, the loading dock is one of the most imperative areas of your business. After all, this is where everything comes in and where it goes out. Unfortunately, it’s also where dangerous and costly accidents can easily occur if proper procedures and equipment are not utilized, particularly when using forklifts in the material transfer zone (MTZ).

Safety must come first, so we’ve put together steps you can take to help create safer loading docks that comply with regulations and accompany your current safety procedures. This loading dock safety checklist is for companies to follow so the inherent risk involved with loading docks is reduced as much as possible, because while cargo is important, your workers are your most important asset. If they’re not safe, then neither is your business.

Loading Dock Safety Checklist

1. Secure the trailer to the dock using either the trailer’s RIG or rear wheel

This rotating-hook, RIG-based vehicle restraint utilizes shadow-hook technology that works with accessible RIGs or blocked RIGs in the case of containers with intermodal chassis

Wheel-based restraints are another option, they engage with trailer wheels to secure vehicles in place. Both automatic and manual options are available

2. Link the gap between the loading dock floor and the trailer bed

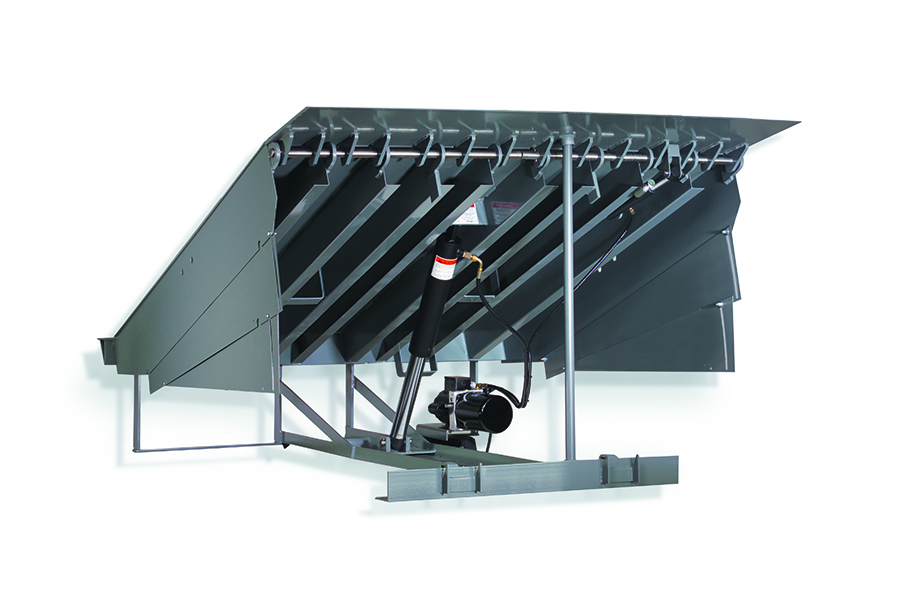

Utilize a dock-leveler, such as hydraulic dock leveler, mechanical dock leveler, air powered dock leveler.

3. Identify damage to trailers during inspections

Perform exterior and interior inspections checking for faulty landing gear and the structural integrity of rear impact guards. Never assume someone else has performed the inspection.

Place trailer stands under the nose of spotted trailers to help prevent trailer up-ending and accidents due to landing gear collapse

4. Help ensure the loading dock is free of debris and water using dock seals

5. Properly establish area protection and pedestrian safety with safety barriers

Fall protection is required by OSHA for the unprotected loading dock edge with a 4' drop off. Installing loading dock safety barriers will help prevent accidents, injuries and damage to products while still allowing full access to load and unload trailers.

6. Improve visibility and communication with a light communication system that provides visual cues and audible warnings to pedestrians on and off of forklifts.

According to OSHA, 70% of all reported accidents could have been avoided with proper safety precautions. While not all encompassing, using these steps along with a well-executed, regulation-abiding safety plan you can help reduce the risk of accidents around the loading dock and keep your business running smoothly.